|

|

|

|

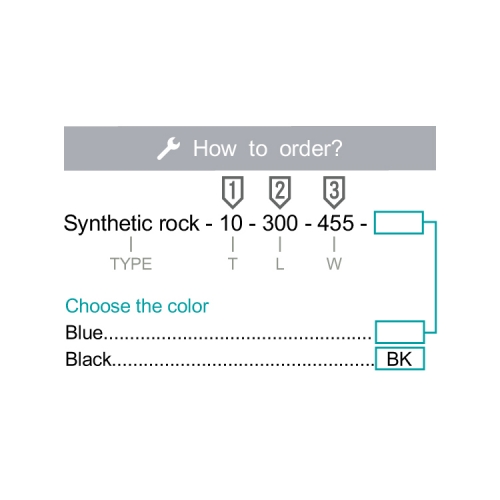

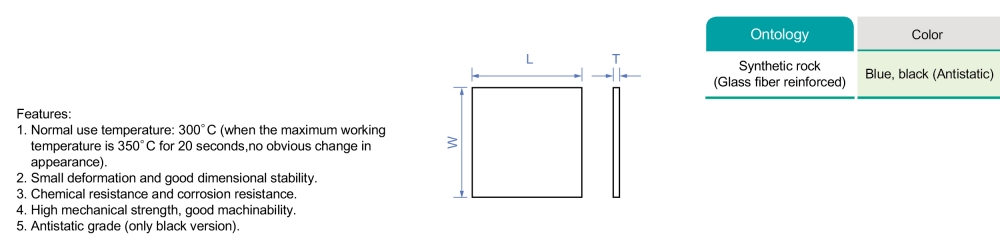

| unit:mm |

| Thickness | 1mm Specify | Whole piece size | Weight(kg) | |

| L | W | |||

| 5 | 10~1000 | 10~1200 | 1020 X 1220 | 11.8 |

| 6 | 14.2 | |||

| 8 | 18.9 | |||

| 10 | 23.6 | |||

| 12 | 28.4 | |||

| 15 | 35.5 | |||

Property table

| Property | Test methods | unit | Test recipe | Product KY-CDMHA |

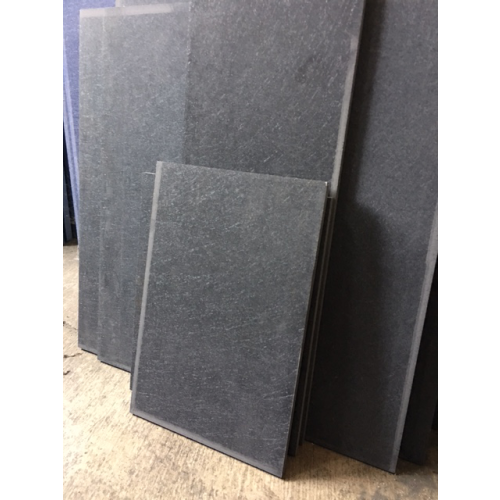

| Color | ISO 1183 Method A |

|

| Black, Blue |

| Density | GB/T 1303.2-2009 | g/cm2 |

| 1.85 |

| (23°C)Flexural strength | GB/T 1303.2-2009 | Mpa | 23°C±2°C | 380 |

| (150°C)Flexural strength | GB/T 1303.2-2009 | Mpa | 150°C±2°C | 120 |

| (23°C)Flexural modulus | GB/T 1303.2-2009 | Mpa | 23°C±2°C | 2.08x104 |

| (150°C)Flexural modulus | GB/T 1303.2-2009 | Mpa | 150°C±2°C | 7.42x103 |

| Surface resistivity | GB/T 1410-2006 | Ω |

| (4.1x107) Only black |

| Absorbency | ISO 62 Method 1 | mg | 24hr/23°C/water M/23°C/50% | 6.3 |

| Lineart expansion | Reference ASTM D696-08el | 10-6/°C |

| 11.2 |

| Conductivity | ISO 8301:1991 | W/m.k |

| 0.430 |

| High temperature resistance | Visual inspection |

| 350°C±5°C,20s, | There is no obvious change in appearance, no delamination, foaming, glue flow, etc. |

| Operating temperature | Visual inspection |

| 180°C±5°C,3000min, | There is no obvious change in appearance, no delamination, foaming, glue flow, etc. |