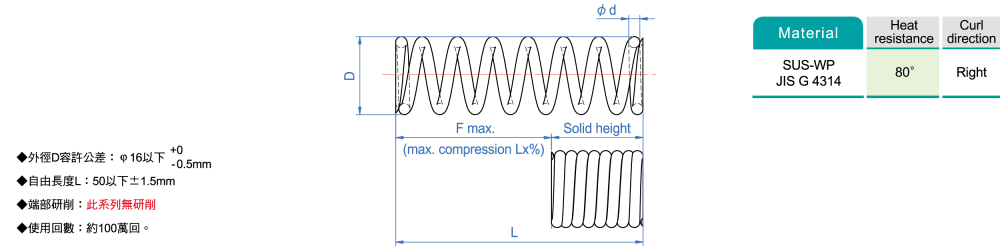

|  |  | | | | | | | D | L | d | Solid height | Max. Compression | Load | Modulus | | L x % | F max. |

|

| 3 | 5 | 0.15 | 1.1 | 70% | 4 | 0.02 | | | 10 | 0.18 | 2.5 | 70% | 7 | 0.04 | | | 15 | 0.18 | 2.5 | 70% | 11 | 0.05 | 0.05 | | 20 | 0.2 | 3.3 | 70% | 14 | 0.07 | N/mm | | 25 | 0.23 | 6.2 | 70% | 18 | 0.09 | | | 30 | 0.23 | 6.2 | 70% | 21 | 0.11 | | | 4 | 5 | 0.18 | 1.2 | 70% | 4 | 0.02 | | | 10 | 0.2 | 1.7 | 70% | 7 | 0.04 | | | 15 | 0.23 | 3 | 70% | 11 | 0.05 | 0.05 | | 20 | 0.23 | 3 | 70% | 14 | 0.07 | N/mm | | 25 | 0.26 | 4.9 | 70% | 18 | 0.09 | | | 30 | 0.26 | 4.9 | 70% | 21 | 0.11 | | | 5 | 5 | 0.2 | 1.2 | 70% | 4 | 0.02 | | | 10 | 0.23 | 1.8 | 70% | 7 | 0.04 | | | 15 | 0.26 | 2.9 | 70% | 11 | 0.05 | 0.05 | | 20 | 0.29 | 4.5 | 70% | 14 | 0.07 | N/mm | | 25 | 0.29 | 4.5 | 70% | 18 | 0.09 | | | 30 | 0.29 | 4.5 | 70% | 21 | 0.11 | | | 6 | 10 | 0.26 | 2 | 70% | 7 | 0.04 | | | 15 | 0.3 | 3.3 | 70% | 11 | 0.05 | | | 20 | 0.3 | 3.3 | 70% | 14 | 0.07 | 0.05 | | 25 | 0.35 | 6.5 | 70% | 18 | 0.09 | N/mm | | 30 | 0.35 | 6.5 | 70% | 21 | 0.11 | | | 35 | 0.35 | 6.5 | 70% | 25 | 0.12 | | | 40 | 0.35 | 6.5 | 70% | 28 | 0.14 | | | 8 | 10 | 0.3 | 1.9 | 70% | 7 | 0.04 | | | 15 | 0.35 | 3.2 | 70% | 11 | 0.05 | | | 20 | 0.35 | 3.2 | 70% | 14 | 0.07 | | | 25 | 0.4 | 5.6 | 70% | 18 | 0.09 | 0.05 | | 30 | 0.4 | 5.6 | 70% | 21 | 0.11 | N/mm | | 35 | 0.4 | 5.6 | 70% | 25 | 0.12 | | | 40 | 0.45 | 9.3 | 70% | 28 | 0.14 | | | 45 | 0.45 | 9.3 | 70% | 32 | 0.16 | | | 50 | 0.45 | 9.3 | 70% | 35 | 0.18 | |

|

※Load calculation formula:Load(N) = Modulus x Compression

※Conversion:kgf=N x 0.102

※Solid height is the reference value,there will be little difference in the production.

| Example:CB151-5-30-0.5

Length 30(ex. Tensile 5mm) to load 25

Load=Modulus X Extension

0.25N=0.05N/mm X 5mm |