|

|

|

|

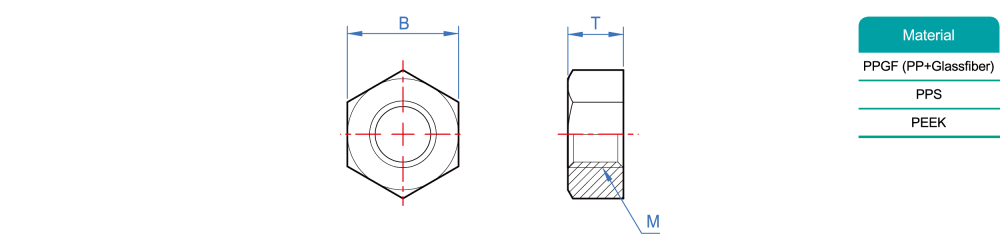

| unit:mm |

| |||

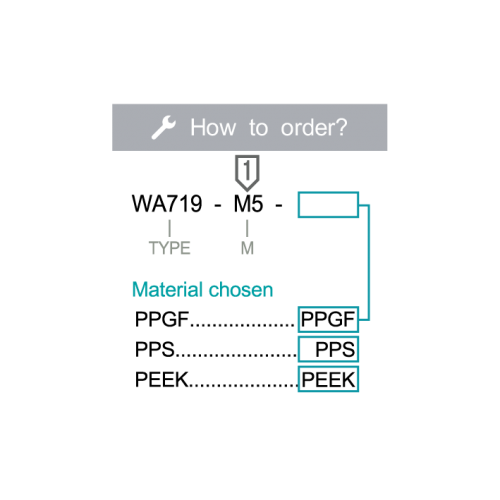

| M | B | T | Pitch | QTY/PKG |

| Item | PPS | PEEK |

| M3 | 5.5 | 2.4 | 0.5 | 50 |

| Light weight | △ | ○ |

| M4 | 7 | 3.2 | 0.7 |

| Water stability | ◎ | △ | |

| M5 | 8 | 4 | 0.8 |

| 強度、鋼性 | ◎ | ○ | |

| M6 | 10 | 5 | 1 |

| 耐衝擊性 | ○ | ○ | |

| M8 | 13 | 6.5 | 1.25 | 50 |

| 耐磨耗性 | ◎ | ◎ |

| M10 | 17 | 8 | 1.5 |

| 耐燃性 | ◎ | ◎ | |

| ※PPS-PolyPhenylenesulfide(聚苯硫化物) |

| 不易燃性 | ◎ | ◎ | ||||

|

| 電氣特性 | ◎ | ◎ | |||||

|

| 耐候性 | ○ | ◎ | |||||

|

| 耐藥品性 | ◎ | ○ | |||||

| ※PEEK-PolyEtherEtherKetone(聚醚醚銅) |

|

|

|

|

| unit:mm |

| M | B | T | Pitch | Each package quantity |

| M3 | 5.5 | 2.4 | 0.5 | 20 |

| M4 | 7 | 3.2 | 0.7 | |

| M5 | 8 | 4 | 0.8 | |

| M6 | 10 | 5 | 1 | |

| M8 | 13 | 6.5 | 1.25 | 10 |

| M10 | 17 | 8 | 1.5 |

| ※PPS-PolyPhenylenesulfide |

| Item | PPS | PEEK |

| PPS is a crystalline engineering plastics, it has excellent heat resistance, can be used continuously at 200 ℃ environment. |

| Light | △ | ○ |

|

| Water stability | ◎ | △ | |

|

| Strength、Rigidity | ◎ | ○ | |

|

| Impact resistance | ○ | ○ | |

|

|

| Abrasion performance | ◎ | ◎ |

| ※PEEK-PolyEtherEtherKetone |

| Flame resistance | ◎ | ◎ |

| PEEK has the highest semi-crystalline engineering plastics, good acid and alkali resistance, in addition to the concentrated sulfuric acid, other chemicals almost impossible to erosion. In addition abrasion performance, water resistance,radiation resistance, heat resistance 180 ℃(UL authenticate). Flame resistance : Comply with UL94 V-0 standard. |

| Non-flammable | ◎ | ◎ |

|

| Electrical specification | ◎ | ◎ | |

|

| Weather fastness | ○ | ◎ | |

| *PPS&PEEK applied to the semiconductor manufacturing apparatus, etching apparatus of printed circuit board, the use of |

| Drug tolerance | ◎ | ○ |

| acid and alkali metal surface treatment equipment, etc. |