|

| 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| unit:mm |

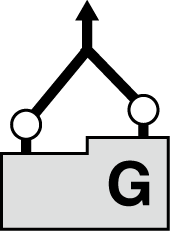

| mit load | Metric Coarse Teeth | American Coarse Teeth | *E | SW | S | A | H | F | D | B | G | C | torque | quality | ||

| Tons |

| Pitch |

| UNC | N•m | (kg) | ||||||||||

| 0.3 | M8 | 1.25 | 5/16" | 18 | 11 | 13 | 6 | 34 | 36 | 98.5 | 14 | 37 | 57 | 42 | 30 | 0.5 |

| 0.63 | M10 | 1.5 | 3/8" | 16 | 16 | 16 | 44 | 60 | ||||||||

| 1 | M12 | 1.75 | 7/16" | 14 | 18 | 18 | 8 | 45 | 100 | |||||||

| 1.2 | M14 | 2 | 1/2" | 13 | 21 | 21 | 10 | 46 | 120 | |||||||

| 1.5 | M16 | 2 | 5/8" | 11 | 24 | 24 | 48 | 150 | ||||||||

| 2 | M18 | 2.5 | 3/4" | 10 | 26 | 27 | 12 | 50 | 44 | 143 | 16.5 | 54 | 82 | 57 | 200 | 1.5 |

| 2.5 | M20 | 7/8" | 9 | 30 | 30 | 58 | 250 | |||||||||

| 3 | M22 | 一 | 一 | 34 | 60 | 300 | ||||||||||

| 4 | M24 | 3 | 1" | 8 | 36 | 36 | 14 | 61 | 400 | |||||||

| 4 | M27 | 3 | 一 | 一 | 38 | 41 | 17 | 60 | 62 | 170 | 22 | 65 | 99 | 80 | 400 | 3 |

| 5 | M30 | 3.5 | 1-1/4" | 7 | 48 | 46 | 82 | 500 | 3.5 | |||||||

| 6 | M33 | 一 | 一 | 54 | 55 | 22 | 60 | 174 | 85 | 600 | ||||||

| 7 | M36-A | 4 |

| 一 | 700 | |||||||||||

| 8 | M36-B | 4 | 一 | 一 | 62 | 55 | 22 | 77 | 79 | 226.5 | 27 | 85 | 123 | 104 | 800 | 6 |

| M39 | 1-1/2" | 6 | ||||||||||||||

| 10 | M42-A | 4.5 | 一 | 一 | 72 | 65 | 106 | 1000 | 6.5 | |||||||

| 15 | M42-B | 4.5 | 一 | 一 | 63 | 65 | 22 | 95 | 90 | 257.5 | 36 | 104 | 158 | 117 | 1500 | 11 |

| M45 | 1-3/4" | 5 | 1600 | |||||||||||||

| 20 | M48 | 5 | 2" | 4.5 | 72 | 75 | 27 | 120 | 2000 | 12 | ||||||

*E size thread length, can be customized.

※The information is not available, please contact the window of each area of CheNa for other sizes.

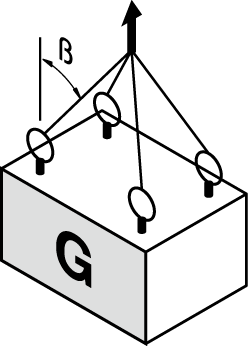

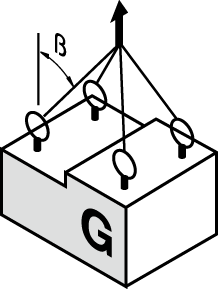

■Side Rotating Ring Load Table

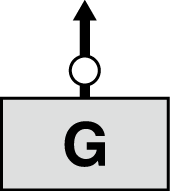

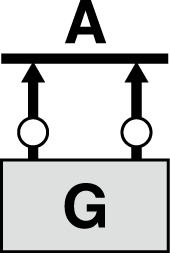

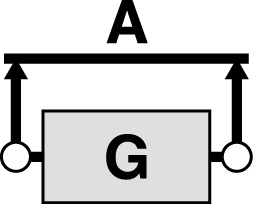

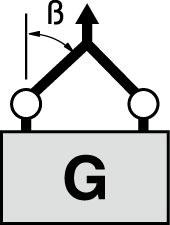

| hanging icon |

|

|

|

|

|

|

|

| hanging icon | ||

| count | 1 | 2 | 1 | 2 | 2 | 2 | 2 | 34 | 34 | 34 | count |

| load angle | 0° | 0° | 90° | 90° | 0°~45° | 45°~60° | asymmetrical | 0°~45° | 45°~60° | asymmetrical | load angle |

| M | load limit Tons | INCH | |||||||||

| M8 | 0.3 | 0.6 | 0.3 | 0.6 | 0.42 | 0.3 | 0.3 | 0.63 | 0.45 | 0.3 | 5/16 |

| M10 | 0.63 | 1.26 | 0.63 | 1.26 | 0.88 | 0.63 | 0.63 | 1.32 | 0.95 | 0.63 | 3/8 |

| M12 | 1 | 2 | 1 | 2 | 1.4 | 1 | 1 | 2.1 | 1.5 | 1 | 7/16 |

| M14 | 1 | 2 | 1 | 2 | 1.4 | 1 | 1 | 2.1 | 1.5 | 1 | 一 |

| M16 | 1.5 | 3 | 1.5 | 3 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 | 5/8 |

| M18 | 2 | 4 | 2 | 4 | 2.8 | 2 | 2 | 4.2 | 3 | 2 | 一 |

| M20 | 2.5 | 5 | 2.5 | 5 | 3.5 | 2.5 | 2.5 | 5.2 | 3.7 | 2.5 | 7/8 |

| M22 | 3 | 6 | 3 | 6 | 4.2 | 3 | 3 | 6.3 | 4.5 | 3 | 一 |

| M24 | 4 | 8 | 4 | 8 | 5.6 | 4 | 4 | 8.4 | 6 | 4 | 1 |

| M27 | 4 | 8 | 4 | 8 | 5.6 | 4 | 4 | 8.4 | 6 | 4 | 一 |

| M30 | 5 | 10 | 5 | 10 | 7 | 5 | 5 | 10.5 | 7.5 | 5 | 1-1/4 |

| M33 | 6 | 12 | 6 | 12 | 8.5 | 6 | 6 | 12.7 | 9 | 6 | 一 |

| M36-A | 7 | 14 | 7 | 14 | 9.8 | 7 | 7 | 14.7 | 10.5 | 7 | 一 |

| M36-B | 8 | 16 | 8 | 16 | 11.2 | 8 | 8 | 16.8 | 12 | 8 | 一 |

| M39 | 8 | 16 | 8 | 16 | 11.2 | 8 | 8 | 16.8 | 12 | 8 | 1-1/2 |

| M42-A | 10 | 20 | 10 | 20 | 14 | 10 | 10 | 21 | 15 | 10 | 一 |

| M42-B | 15 | 30 | 15 | 30 | 21 | 15 | 15 | 31.5 | 22.5 | 15 | 一 |

| M45 | 15 | 30 | 15 | 30 | 21 | 15 | 15 | 31.5 | 22.5 | 15 | 1-3/4 |

| M48 | 20 | 40 | 20 | 40 | 28 | 20 | 20 | 42 | 30 | 20 | 2 |

※Notice

•The ring body can be rotated with the direction of the force to adjust the force angle.

• Different load directions can lift different loads, but 4 times the safety factor is guaranteed.

•Complete thread specifications and wide range of rated loads can be customized according to customer requirements.

• 100% passed the 6g go-stop gauge inspection and can be adapted to precise threaded holes.

•The inner space of the ring body is large and can be linked with various hooks of spreaders. The ring body has a built-in positioning circlip device, which is more convenient to control and can be placed flat at any angle. The outer hexagon + inner hexagon design is convenient and quick to install. .

• The thread is made of alloy steel 42CrMo by precision forging, the tensile strength σb before heat treatment is 1080MPa, and the mechanical properties are improved after quenching and tempering. The surface of the lifting ring is electrostatically sprayed to improve the surface anti-corrosion ability.